|

| |

Product Classification : Can Making

|

|

AEPS-100 Automatic End Profile Systems

|

|

AEPS-100 Automatic End Profile Systems is used to test end sizes. Excellent performance,

adopt optical testing technology, accurately measures end sizes.

Inaccurate end sizes lead to bad quality double seams, such ascut seam, head cover, fake seam.

It is hard to measure all end profile datas without AEPS-100.

Old destructive testing ways take long time, inaccurate, and different handlers get different results.

AEPS-100 adopt optical testing technology, accurately measures all the end sizes.

|

|

|

SCG-200 Seamer clearance Gauge

|

The CanNeed SCG-200 Seamer clearance Gauge, a quick and accurate way to set up seamers.To measure the roll height off the chuck and the lateral distance between the roll and chuck.

The Clearance Gauge allows users to do predictive maintenance on their seamers before they go out of specifications. The clearance gauge is able to not only quickly and accurately set up the seamer, but makes sure that all the seamer heads are performing perfectly as near as possible to the nominal value.

Instead of focusing on checking seams after the double seam is already closed, the Clearance Gauge helps optimize the can seaming process by taking out variations between the different seamer heads and optimizing the seamer itself!

Today, covering most seamer models, these seamers show a clear and dramatic performance improvements by using this gauge.

|

|

|

SeamSight®-C Full Automatic Seam Monitor

|

The CanNeed Seam Sight® professional seam measuring software will do the line positioning automatically and the measurement to be finished within 1 second!

The software also adopted the data base management system, all the measurement data will be restored in the system data base, so that to enhance the software performance and more convenience in data management.

The result statistic andresult chart has been added in the data base screen for overview and comparison. Meanwhile, the measurement screen has been optimized for a vivid result display.

|

|

|

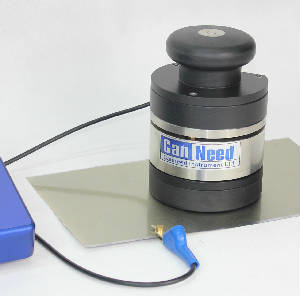

EPH-100 End Panel Holder-for Digital Enamel Rater

|

|

EPH-100 End Panel Holder-for Digital Enamel Rater

|

|

|

AXL-4000 Axial Load Tester

|

|

The "CanNeed AXL-4000 Axial Load Tester" measures the axial force resistance of beverage cans in Newton. The can is placed in a support and gradually forced upwards against the pressure plate. The space between the support and the top plate can be altered with spacers. The can crashes after the peak force has been applied that the can is capable of resisting. The maximum value can now be read in the display.

|

|

|

ACH-100 Aerosol Curl Height Gauge

|

|

The Canneed ACH-100 Aerosol Curl Height Gauge is used for measuring

the contact height of the curl 1" aperture of aerosol cans.

ACH-100 is the Industry Standard.

The gauge is first calibrated by setting the calibration ring on the gauge. In this case the dial has to indicate the value of 4.25 mm.

The measurement on the can is then inserting the gauge up to the shank into the can and then slowly releasing the button.

|

|

|

AXL-CAL Calibration Cell for Axial Load Tester

|

|

The CanNeed AXL-CAL use to calibrate the AXL-4000 Axial Load Tester. Place the AXL-CAL into the testing platform and rise up gradually until reaches the top plate, then the AXL-CAL will display the real time pressure, compare the value that displaying on the AXL-4000 to make the calibration.

|

|

|

CSS 2000 Seam Saw

|

|

The CanNeed "CSS-2000 Seam saw" is a special seam circular saw with double cut for double seam inspections. The CSS 2000 was specially designed for 2- and 3-piece cans. Also aerosol-cans may be sawed with this saw. The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on Caneed series Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

Seam Sight 3B Portable Full Automatic Seam Monitor

|

|

The CanNeed "Seam Sight 3B Portable Full Automatic Seam Monitor" is so small and portable to work with a laptop. It was packed with the CSS-P2 into a suitcase, specially designed for those who always on business trip.

The "Seam Sight 3B Portable Full Automatic Seam Monitor" has adopted the advanced optical system and Golden LensTM video capture device, which interference-free of external light source and ensured the high image definition and the measurement accuracy. The Seam SightTM system is equipped with the new seam measuring software - Seam SightTM.

|

|

|

DER-400 Digital Enamel Rater

|

|

The CanNeed DER-400 Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

|

|

|

CTG-310 Coating Thickness Gauge

|

|

The Canneed ¡°CTG-310 Coating Thickness Gauge¡± provides a computer enhanced method of rapidly assessing lacquer film weight of both internal and external coatings on beverage and food cans, and also tinplate.

The system provides the following benefits to the Can and End manufacturer:

|

|

|

CSS-2000 seam saw

|

|

The CanNeed ¡°CSS-2000 Seam saw¡± is a special seam circular saw with double cut for double seam inspections. The CSS 200 was specially designed for 2- and 3-piece cans. Also aerosol-cans may be sawed with this saw. The nitrated blades achieve together with the speed of approx. 1.000 r/min. a very plain cut surface. The seam image on Caneed series Automatic Seam Computer (Video Seam Monitors), and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

STR-100 Seam Stripper

|

The CanNeed automatic "STR-100 Seam Stripper" is a sensible, affordable, teardown method to prepare the double seam teardown analysis. One fast, safe teardown operation without damaging or distorting the cover hook. Reduce teardown time for more frequent inspections. Tooling quick change in few seconds. Models are available for most common can sizes of beverage, food, and aerosol cans. When ordering, the end diameter and can height must be specified so that the appropriate change parts are included. Efficient cut and strip both aluminium and steel cans in a single motion. 10 seconds per can. Eliminates the repetitious actions by hand.

|

|

|

Seam-X-Lab X-Ray Automatic Seam Scanner

|

The CanNeed Seam-X-Lab is suitable for laboratory

Can open or close the door automatically£¬put in or take out the sample cans by manual operation

The CanNeed Seam-X-Line is suitable for laboratory

Can open or close the door automatically£¬automatic sampling

Purpose:

The CanNeed Seam-X-lab Automatic Seam Scanner adopts non-destructive measurement method to measure the seam quality, suitable for measuring the aluminum cans, steel cans , aluminum-iron composite cans and etc. It¡¯s applicable for laboratory or producing department.

Advantages:

1.Non-destructive measurement, avoid wasting samples

2.Non-destructive measurement, avoid environmental pollution and save handling charges

3.High sampling frequency, reduce the isolation inferior

4.High sampling frequency, cost saving

5.Can track the chucks corresponding to the unqualified products

6.360-degree fully scan measurement

7.Can be suitable for various types of cans

8.Higher accuracy

9.Avoid manual measurement error

10.Durable

11.Accord with the worldwide safety standards

|

|

|

CSS-100B Anti-noise seam saw

|

The CanNeed CSS-100B Anti-noise seam saw

The saw is provided with an anti-noise design and a special guide for 2- and 3-piece cans (65 mm dia.).

Special seam circular saw with double cut for can double seam inspections.

|

|

|

ABT-200 Burst Buckling Tester For Aerosol Cans

|

Canneed ABT-200 Burst Buckling Tester for Aerosol Cans is used to test the buckle value of bottom and end (dome) of aerosol cans and the pressure at which the can bursts.

Equip with the special designed clamp device, ABT-200 is able to test the buckle value of free ends (dome) or bottom of aerosol cans independently.

The professional analyzing software of ABT-200 is able to display the pressure curve, monitor and record three buckle values: end buckle value, bottom buckle value and burst value. The database system manages the measurement result and curve, and the system will carry out the testing process automatically, so that no manual operation needed during the testing process.

|

|

|

CSS-P3 Portable Seam Saw

|

|

The CanNeed "CSS-P2 Portable Seam Saw" is a special seam circular saw with double cut for can double seam inspections. The CSS-P2 was specially designed for 2- and 3-piece cans. Also aerosol-cans may be sawed with this saw. The nitrated blades achieve a very plain cut surface. The seam image on "VSM Automatic Seam Monitor", and automatic seam measuring systems gets thereby very clear and improves measurement speed and reliability.

|

|

|

CSS-1000 Anti-noise Seam Saw

|

The CanNeed ¡°CSS-1000 Anti-noise Seam Saw¡± is provided with an anti-noise design and a special guide

for 2-and 3-piece cans with 65mm dia, such as beer cans and 209 cans. The cutting process is so precise, quick, safe and convenient to ensure precise cutting effects without distorting the cans. The seam image on Canneed series Seam Sight TM automatic seam measuring systems gets thereby every clear and improves measurement speed and reliability.

|

|

|

MDER-10 Multi-station Digital Enamel Rater for Ends (10 Stations)

|

|

In order to meet the needs of testing several ends at one time, CanNeed designed MDER-10 and MDER-20 Multi-station Digital Enamel Rater for Ends. MDER-10 can finish testing the current of 10 ends in 4 seconds. If connected with two ten-hole fixing holders, it can test 10 ends at one time. The diameters of ends are 50-99mm.

|

|

|

CTG-HP Hover Probe

|

|

The CanNeed CTG-HP Hover Probe is combined with CTG-300/CTG-310 Coating Thickness Gauge to test the lacquer film coating thickness and weight per unit area.

|

|

|

DER-4 Digital Enamel Rater

|

|

The CanNeed DER-4 Digital Enamel Rater is able to detect the exposed metal position more easily compare to the former models. The reformative electronic design makes it more sensitive, reliable and accurate. The anticorrosion characteristic of the enhanced can body support is ensured its durability. The film coated buttons are more durable and with better corrosion resistance.

|

|

|

RPG-100 Roll profile Gauge

|

|

The RPG-100 is able to scan profiles of seaming Rolls and Chucks (or other tooling - including carbide and ceramic tools) easily and quickly. The system can be used for acceptance testing for new seaming rolls or chucks, for quality assurance purposes and for stress analysis. Monitor tooling wear to replace rolls and chucks only when they need to be replaced

|

|

|

CBT-200 Buckle Tester Bottom for Can

|

|

The "Canneed CBT-200 Buckle Tester Bottom for Cans" determines the exact pressure at which the can bottom begins to buckle respectively the dome reverses.

The empty flanged can or straight wall can is placed in the holder. After covering the device with a plexiglass hood pressure is applied. The can is sealed with a rubber o-ring structure. Fast pressure increase up to 5 bar (programmable to just bellow the expected buckle value), from there the "speed of pressure increase" may be set within the device. The test is terminated as soon as the can buckles. The maximum pressure value is shown in the display.

|

|

|

SCG-200 Seamer clearance Gauge

|

|

The CanNeed SCG-200 Seamer clearance Gauge, a quick and accurate way to set up seamers.To measure the roll height off the chuck and the lateral distance between the roll and chuck.

|

|

|

PTT-300 Pop and Tear Tester

|

|

The CanNeed "PTT-300 Pop & Tear Tester" was developed for testing different kinds of easy open ends.

Applicable to 7 different types of ends: RP / SOT / EO / OVAL / FSE / SNAP and ALUFIX.

Adopted 5 different testing modes: RP / SOT / EO / OVAL and SNAP.

Operators just need to hook the ring and press "test" button, then the PTT-300 will do the test automatically. During the testing process, the microprocessor will monitor and record the max. Pop and Tear force. With different sizes of the clamps, it is able to test different sizes of ends.

|

|

|

CSS-300 Seam Saw

|

|

The CanNeed "CSS-300 Seam saw" is a special seam saw with double cut for double seam inspections. The CSS 300 has specially designed for the irregular shaped cans, like rectangle cans, oval cans, etc.Also aerosol-cans can also be sawed with the saw. The nitrated blades achieve together with the speed of approx. 1.000 r/min. so that comes a very plain cut surface. The seam image on the Canneed series of Automatic Seam Monitors gets thereby very clear and improves measurement speed and reliability.

|

|

|

CND-TRK-300 Oven Temperature Tracker

|

|

The CanNeed CND-TRK-300 Oven Temperature Tracker is a professional oven temperature curve inspection system for the coating industry, it is including the data logger, heat insulation case, software (Chinese / English) and thermocouples.

|

|

|

EMS-200 Multiple Lid Measurement Station

|

The CanNeed EMS-200 Multiple Lid Measurement Station is for measuring the End Curl outer diameter, End Curl height and Countersink.

Place the ends on the testing platform, select the measure points, then press "start". The three pneumatic controlled sensors will start to measure the sample ends automatically at the same time. The sample ends will be rolled automatically to change the measure points. For every circle, the amount of measure points can be set from 1 to 50.

Measurement results can be exported by the RS232 data wire. Calibrate by the standard gauge and controlled by the touch-screen PLC system.

|

|

|

ABT-100 Burst Buckling Tester for aerosol cans

|

The "Canneed ABT-100 Burst Buckling Tester for Aerosol Cans " is used to determine the buckle value of bottom (dome) and Top end of aerosol cans and the pressure at which the can bursts. With the special designed clamp, it is able to measure the dome or bottom free ends independently. At high pressures from approximately 22 - 28 bar, it may happen that deformations of the valve and a higher burst pressure.

|

|

|

STG-200-D Seam thickness gauge(digital)

|

|

The CanNeed STG-200-D Seam thickness gauge can be used to measure Seam thickness.

With measure angle compensation. The center mesure point can be adjusted.

Cans can be auto- positoned in the center easily during measuring .

With the Mitutoyo 0.01mm Resolution Digital Indicator.

If you purchase the adapter and cable, the instrument can communicate with a computer.

|

|

"If you can not find the product you need, please contact us or leave a message."

|

|